Epoxy floor coatings are a durable and aesthetically appealing solution for various spaces, including garages, warehouses, industrial facilities, and residential interiors. Choosing the right epoxy floor coating services ensures longevity, safety, and a polished finish that enhances your space. This guide will help you navigate the selection process and find the perfect coating epoxy floor solution for your needs.

Understanding Epoxy Floor Coatings

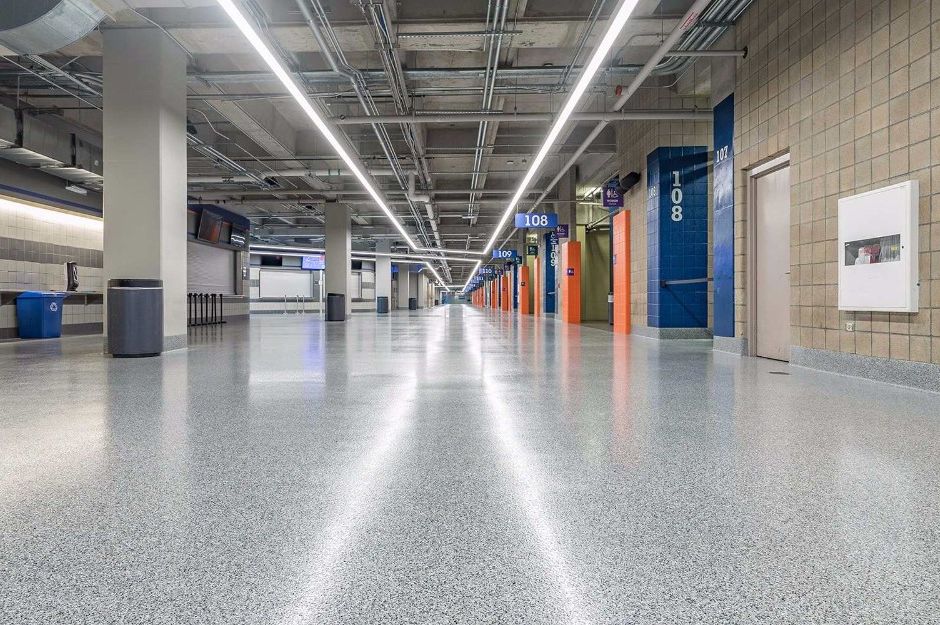

Epoxy is a resin-based material that forms a hard, protective layer over floors, making them resistant to stains, wear, and impact. Different types of epoxy coatings cater to varying needs, ensuring both functional and aesthetic benefits.

Types of Epoxy Floor Coatings

- Self-Leveling Epoxy – Best for smooth, seamless surfaces in commercial and industrial settings.

- Metallic Epoxy – Creates a glossy, decorative finish ideal for showrooms and luxury interiors.

- Epoxy Mortar Coating – Highly durable and suitable for high-traffic areas and heavy machinery.

- Gravel Epoxy – Designed for decorative appeal with embedded stones for a unique look.

- Anti-Static Epoxy – Ideal for environments where electrical conductivity must be controlled, such as laboratories and server rooms.

Factors to Consider When Choosing an Epoxy Floor Coating Service

1. Durability Requirements

Assess the level of foot traffic, vehicle use, or potential chemical exposure your floor will endure. Epoxy floor coating services offer different coatings tailored for specific needs.

2. Surface Preparation Methods

Proper surface preparation is key to the longevity of an epoxy coating. Ensure that the service provider includes thorough cleaning, crack repairs, and priming in their process.

3. Aesthetic Preferences

From solid colours to decorative finishes, coating epoxy floor options range in design. Consider whether you want a glossy or matte look, patterns, or colour variations.

4. Slip Resistance and Safety Features

Certain epoxy coatings offer slip-resistant additives, making them ideal for spaces requiring extra safety measures, such as hospitals and kitchens.

5. Installation Time and Budget

Different coatings have varying curing times, impacting how quickly the space can be used. Balancing quality with budget constraints is crucial in selecting the right service provider.

6. Maintenance Needs

Some epoxy coatings require minimal upkeep, while others may need regular reapplications. Understanding long-term maintenance costs can help you make an informed decision.

Why Hire Professional Epoxy Floor Coating Services?

While DIY epoxy kits are available, professional epoxy floor coating services in Brisbane provide expertise, superior materials, and long-lasting results. Here’s why professionals are the best choice:

- Expert Surface Preparation – Ensures proper adhesion and durability.

- High-Quality Materials – Professional-grade epoxy is stronger and more resistant than store-bought versions.

- Precision Application – Experts ensure an even, bubble-free finish.

- Custom Solutions – Tailored coatings that fit your exact needs.

- Long-Term Cost Savings – Professional installation reduces the risk of peeling and premature wear, saving on future repairs.

Conclusion

Selecting the right epoxy floor coating services ensures a strong, stylish, and long-lasting flooring solution for your space. Whether you need durability for industrial use or an elegant finish for a showroom, professional services provide the best results. Investing in the right coating epoxy floor application not only enhances your space but also offers long-term value and protection. Choose wisely to enjoy a functional and visually appealing floor that meets your specific needs.

FAQs

1. How long does it take to install an epoxy floor coating?

Depending on the type and curing time, installation can take 1 to 5 days.

2. Is epoxy flooring suitable for outdoor spaces?

Yes, but special UV-resistant epoxy formulations should be used to prevent fading and degradation.

3. Can epoxy floors be installed over existing tiles or concrete?

Yes, but proper surface preparation is necessary to ensure adhesion and durability.

4. How do I maintain my epoxy-coated floor?

Regular sweeping, occasional mopping, and avoiding harsh chemicals help maintain the finish.

5. Are epoxy floors resistant to heavy machinery and chemicals?

Yes, industrial-grade epoxy coatings are designed to withstand heavy loads and chemical spills.